In the blown film industry, maintaining cost-efficiency and reducing waste is critical. Let’s delve into how Gravimetric Blender can transform your production processes, promoting waste reduction and energy efficiency, particularly in the realm of three-layer co-extrusion.

- Addressing Waste in the Blown Film Industry:

In the complex process of blown film production, waste management is a key challenge. From excess material to defective films, the cost implications of waste can quickly escalate. - Engineering Cost-Efficiency in Blown Film Production:

Balancing cost reduction with high-quality output is a nuanced task. However, with innovative tools like Gravimetric Blenders and clever strategies, this balance becomes achievable. - The Impact of Gravimetric Blenders:

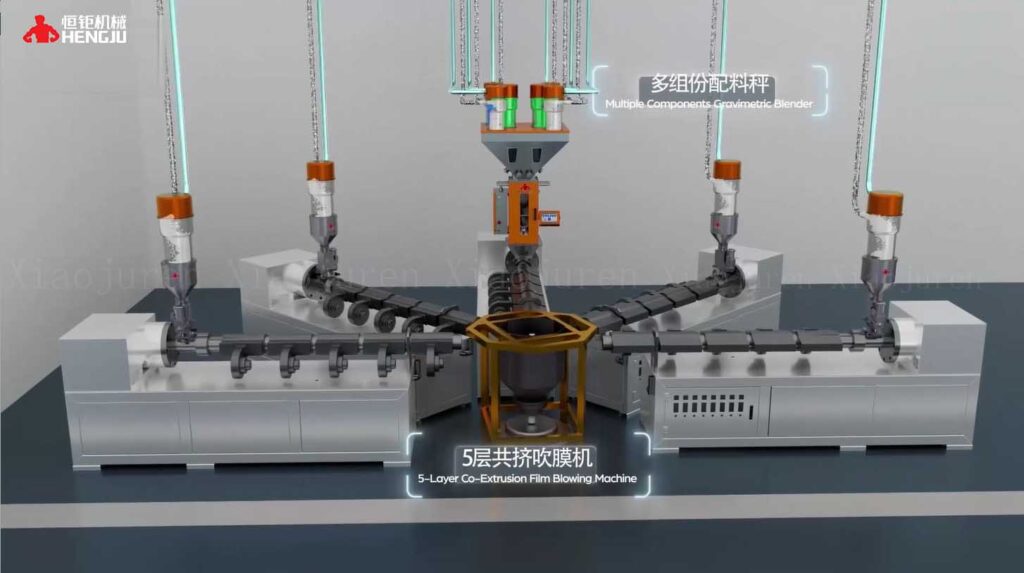

Gravimetric Blenders are a game-changer in the blown film industry, offering numerous benefits from maintaining recipe confidentiality to boosting energy efficiency. They ensure precise measurement and blending of materials, which minimizes excess usage and reduces the risk of producing faulty films.

4.Benefits of Gravimetric Blenders in Three-Layer Co-Extrusion:

- Precision: Gravimetric Blenders offer unbeatable precision, optimizing material usage, and significantly reducing waste.

- Efficiency: These devices streamline the blending process, enhancing overall operational efficiency, and cutting costs.

- Quality Assurance: By ensuring accurate blending, Gravimetric Blenders help maintain the quality of the final product, reducing defects and waste.

- Energy Efficiency: Gravimetric Blenders improve energy efficiency in three-layer co-extrusion processes, further cutting costs.

- Confidentiality: These blenders help keep your formulas confidential, safeguarding your competitive edge in the market.

Gravimetric Blenders offer a potent solution for waste reduction and cost optimization in the blown film industry. By integrating these devices into your production line – especially in three-layer co-extrusion processes – you can boost operational efficiency, reduce waste, and lower production costs.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico