In the production of piping bags, achieving precision in material measurement and blending is crucial for maintaining high product standards. Gravimetric dosing systems offer a sophisticated solution to this challenge, providing precise weight-based control of raw materials. This article explores the advantages and specific uses of gravimetric dosing systems in the manufacturing of piping bags.

Understanding Gravimetric Dosing Systems

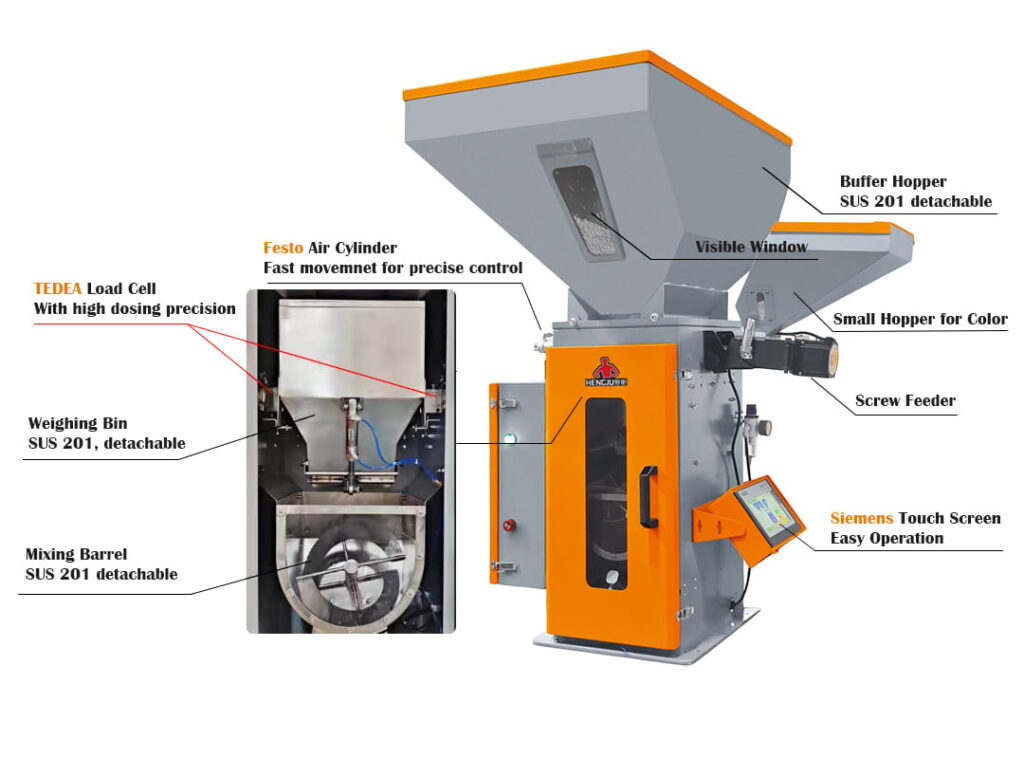

Gravimetric dosing systems measure and dispense raw materials based on their weight, rather than volume. This method ensures a higher degree of accuracy and consistency, which is essential for maintaining the quality of products like piping bags. By continuously monitoring the weight of materials, these systems deliver precise amounts needed for each batch, ensuring consistent product properties.

Key Benefits of Gravimetric Dosing Systems in Piping Bag Manufacturing

- Unmatched Accuracy

- The primary advantage of gravimetric dosing systems is their ability to measure raw materials with exceptional precision. This accuracy is critical in ensuring that piping bags have consistent thickness, strength, and durability.

- Material Efficiency

- By delivering the exact amount of material required for each production cycle, gravimetric systems help reduce waste. This efficient use of materials lowers production costs and supports environmentally friendly manufacturing practices.

- Enhanced Product Quality

- Precise material measurement ensures that each piping bag produced meets high-quality standards. This uniformity reduces the likelihood of defects and enhances the overall reliability of the product.

- Cost Reduction

- The efficiency of gravimetric dosing systems translates to lower operational costs. By minimizing material wastage and optimizing the use of additives, manufacturers can achieve significant cost savings.

- Adaptability and Scalability

- Gravimetric dosing systems can easily be adapted to different production requirements, making them suitable for both small-scale and large-scale manufacturing. Their scalability ensures they can grow with the production needs.

Applications in Piping Bag Production

1. Precise Material Blending

Piping bags are often made from a combination of polyethylene and other additives that enhance their functionality. Gravimetric dosing systems ensure that these materials are blended accurately, resulting in a final product that consistently meets design specifications.

2. Controlled Additive Dispersion

For piping bags that require specific additives for color, texture, or other properties, gravimetric systems offer precise control. This ensures that additives are evenly distributed, maintaining uniform quality across all products.

3. Continuous Production Optimization

The integration of gravimetric dosing systems into the production line allows for real-time adjustments. This continuous monitoring helps maintain optimal production conditions, reducing the risk of errors and ensuring consistent product output.

Gravimetric dosing systems have revolutionized the manufacturing of piping bags by providing precise, efficient, and adaptable solutions for material measurement and blending. These systems enhance product quality, reduce waste, and lower production costs, making them an invaluable tool in the plastics industry. As the demand for high-quality piping bags continues to rise, the implementation of gravimetric dosing systems will be key to maintaining competitive advantage and operational excellence.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico