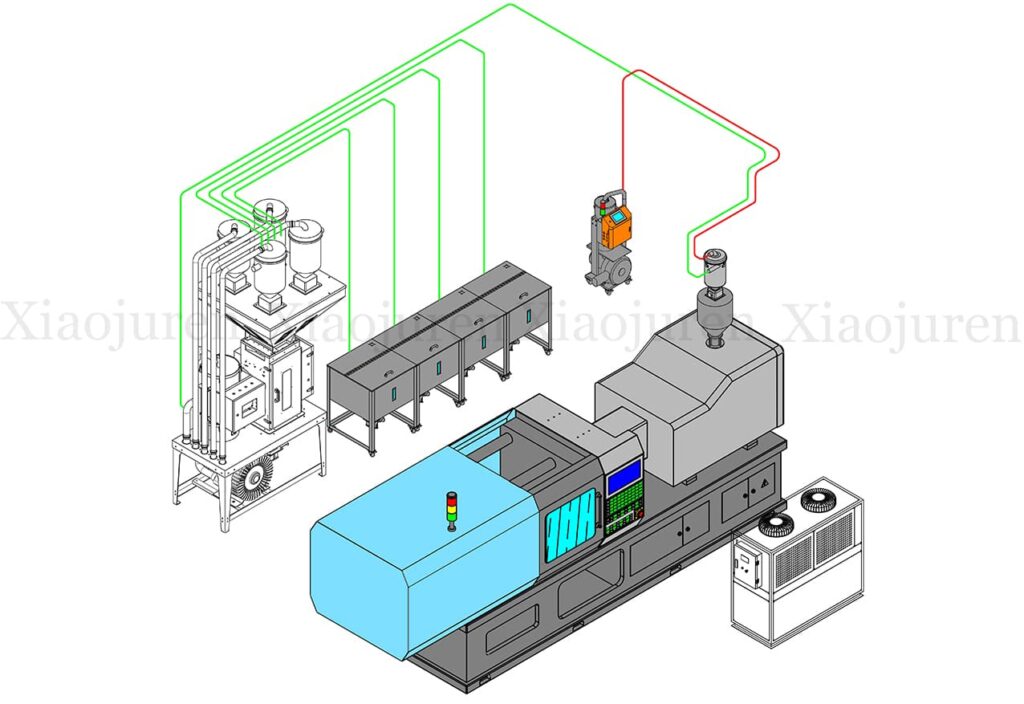

The Two-Machine Integrated Gravimetric Blender, a combination of a weighing mixer and a suction machine, stands as a revolutionary addition to the field of plastic auxiliary forming equipment. This comprehensive article delves into the operating principle, advantages, key technologies, applications, and how it facilitates factory automation.

Gravimetric Blender Operating Principle

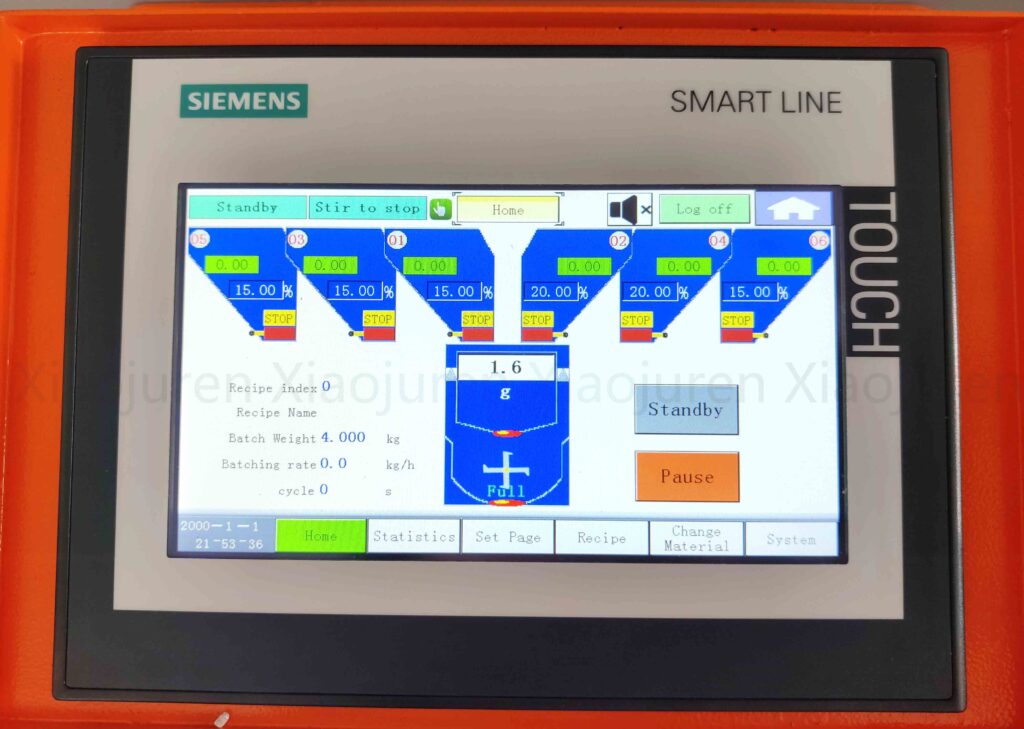

The Gravimetric Batch Blender operates on the principle of gravimetric blending, ensuring precise weight-based measurement and blending of materials. The suction machine, using vacuum conveying, transports these materials from storage to the blending chamber. This combination guarantees a seamless, efficient, and high-quality blending process.

Gravimetric Blender Key Advantages

The two-machine Gravimetric Batch Blender provides several advantages:

- Highest Accuracy: Advanced algorithms, autonomous optimization, automatic calibration, and anti-vibration features ensure the highest accuracy.

- Versatility: The machine can dose 4-8 components, making it adaptable to various blending requirements.

- Efficiency: With the capacity to store up to 100 recipes for later use, the blender enhances operational efficiency.

- Quality Control: The integrated Etherhet interface enables transmission of material proportion data, aiding in quality control.

- Increased Conveying Capacity: The vacuum blower, equipped with a high-power motor, large-sized hose, and hopper, ensures a bigger conveying capacity.

- Durability: The adoption of pure copper coil in the blower motor ensures stable and durable performance.

- Resilience: The aluminum alloy high-pressure impeller is resistant to high temperatures, corrosion, and rust, ensuring longevity.

Key Technologies and Applications

The two-machine integrated Gravimetric Batch Blender, with its precise blending and efficient transportation of materials, is pivotal in various plastic production methodologies, including injection molding, extrusion, and blow molding.

Facilitating Factory Automation

The Gravimetric Batch Blender, with its autonomous optimization and automatic calibration features, paves the way for factory automation. By mechanizing the blending process, it reduces manual intervention, thereby boosting productivity and efficiency.

In conclusion, the two-machine integrated Gravimetric Batch Blender, with its precise blending capabilities, versatility, efficiency, and facilitation of factory automation, stands as an invaluable asset in the plastic auxiliary forming equipment industry. Its wide-ranging applications and benefits make it an indispensable tool, revolutionizing the landscape of the plastic production industry.

If you need a central conveying system, please visit https://centralconveyingsystem.com/

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico