Material handling and equipment are the backbone of any industry. Among them, the Gravimetric Blender stands out as a key component in modern handling systems.

Material Handling and Equipment Overview

Material handling involves managing, controlling, and transporting materials within a facility or site. The right equipment plays a critical role in ensuring efficiency, safety, and productivity.

Gravimetric Blender in Handling Systems

The Gravimetric Blender is a standout piece of equipment. It offers precise control in the blending and distribution of materials. This is especially crucial in industries where consistency and accuracy are paramount.

-1024x704.jpg)

Safety and Sustainability

In addition to its performance benefits, the Gravimetric Blender also contributes to workplace safety and sustainability. Its built-in safety features protect operators, while its energy-efficient design aligns with green practices.

As the demands of industries evolve, the role of the Gravimetric Blender in material handling systems is set to expand. Its blend of efficiency, accuracy, and sustainability makes it a key piece of equipment for the future.

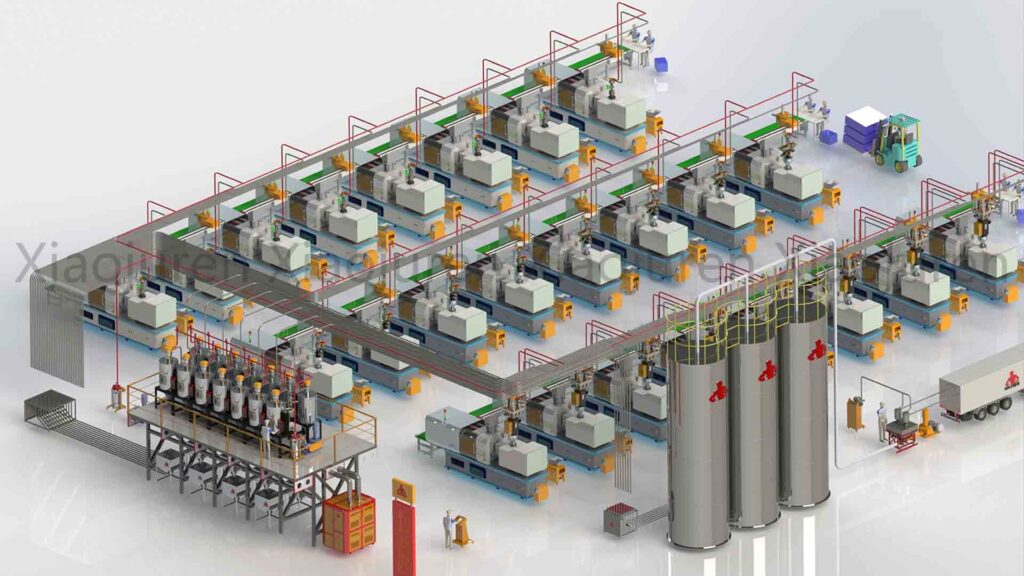

The central conveying system is a pivotal element of industrial material handling. When integrated with advanced equipment like the Gravimetric Blender, it can significantly amplify efficiency and precision.

Central Conveying Systems

Central conveying systems are designed to transport materials from one location to another within a facility. They streamline operations, minimize manual handling, and improve productivity.

The Gravimetric Blender in Central Conveying Systems

Incorporating the Gravimetric Blender into a central conveying system can greatly enhance its performance. This system has the ability to accurately blend and distribute materials, ensuring consistent quality throughout the process.

Integration Benefits

The integration of Gravimetric Blender into central conveying systems offers numerous benefits. It ensures precise control of material quantities, reduces waste, and boosts production efficiency. Plus, the automated system minimizes manual intervention, promoting workplace safety.

Sustainability and Future Prospects

The Gravimetric Blender’s energy-efficient operation aligns perfectly with today’s emphasis on sustainable practices. Looking forward, the integration of such advanced equipment in central conveying systems is expected to become more prevalent as industries strive for greater efficiency and sustainability.

The Gravimetric Blender’s role in enhancing central conveying systems cements its position as a vital player in material handling. Its precision, efficiency, and sustainability not only improve current operations, but also pave the way for future advancements in industrial material handling.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico