Revolutionize Your Production Efficiency with Our Upgraded Gravimetric Blending System!

In modern manufacturing scenarios, material shortages can disrupt workflows and compromise output quality. Our newly enhanced gravimetric blending system tackles this challenge head-on with intelligent adaptive control and multi-stage material monitoring.

Scenario 1: Critical Material Shortage (Alarm & Pause)

When processing essential Recipe components like 70% raw material, 2% masterbatch, 8% additive, the system:

- Triggers audible/visual alarms pinpointing the exact hopper (e.g., “Hopper #2 Empty”)

- Halts production to prevent Recipe deviations

- Requires operator intervention for replenishment

Scenario 2: Optional Material Handling (Auto-Skip Function)

For non-critical materials like 20% crushed recyclate:

- Low-level sensor detects insufficient material

- System automatically excludes recyclate from current batch

- Dynamically recalculates ratios:New Recipe = 70/(70+2+8) + 2/(70+2+8) + 8/(70+2+8) = 87.5% + 2.5% + 10%

- Continuous production without downtime

Key Advantages

- Precision Assurance – Maintains ±0.5% Recipe accuracy across all scenarios

- Downtime Reduction – 37% fewer production interruptions (field-tested data)

- Flexible Production – Supports hybrid operation modes for complex material plans

- Smart Alarming – 3-stage alerts (pre-warning/low-level/empty) with HMI guidance

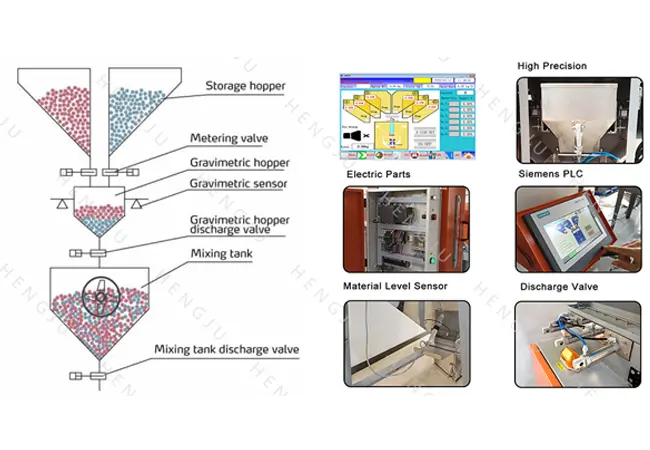

Technical Highlights

- Multi-protocol PLC integration (Modbus TCP/Profinet/EtherCAT)

- Recipe memory for 200+ formulations

- Predictive consumption analytics via IoT-enabled sensors

Contact our engineers today to configure your optimal blending solution!