In the plastic injection molding industry(also called IMM), the use of gravimetric batch blenders has revolutionized the material preparation process. This advanced equipment stands in stark contrast to traditional manual batching methods, offering significant advantages in automation, precision, and labor savings.

Manual batching, the traditional approach, relies heavily on human operators to measure and mix raw materials. This method is prone to errors, as human judgment and physical limitations can lead to inconsistent mixtures. Moreover, the process is labor-intensive, requiring multiple personnel to handle, measure, and mix the materials, which can be both time-consuming and costly.

On the other hand, gravimetric batch blenders automate the entire batching process. These machines use precise load cell and advanced control systems to measure and mix materials with remarkable accuracy ±0.5%. The automation not only eliminates human error but also significantly reduces the need for manual labor. Operators can simply input the desired mixture ratios, and the machine will handle the rest, ensuring consistent and high-quality mixtures.

The precision of gravimetric blenders is particularly crucial in the plastic injection molding industry. Inconsistent mixtures can lead to defects in the final product, such as porosity, warping, and color variations. By ensuring accurate and consistent mixtures, gravimetric blenders help to improve product quality and reduce waste.

In addition to precision, gravimetric blenders offer significant labor savings. With automation, fewer operators are needed to handle the material preparation process. This not only reduces labor costs but also allows personnel to be reallocated to other tasks, improving overall efficiency.

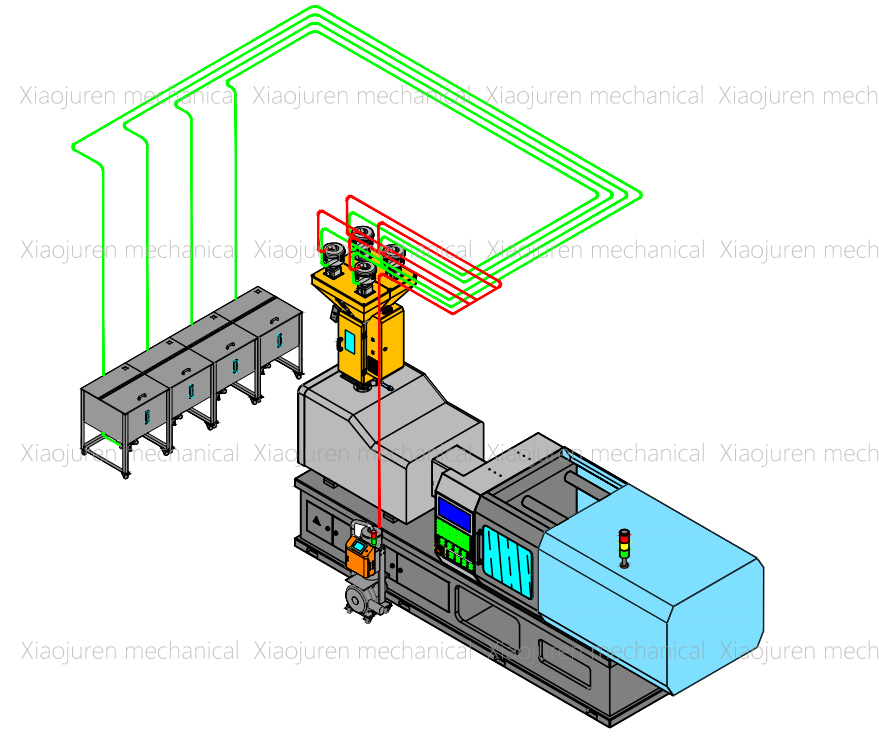

In conclusion, the application of gravimetric blenders in the plastic injection molding industry represents a significant advancement over traditional manual batching methods. By offering automation, precision, and labor savings, gravimetric blenders help to improve product quality, reduce waste, and increase efficiency. As the industry continues to evolve, the adoption of gravimetric blenders will likely become even more widespread, further transforming the material preparation process in plastic injection molding.

Xiaojuren, with wide experience in plastic industry, can provide turn-key solution including raw material unpacking, storage silo, automatic blending, dehumidifying drying, and central conveying systems for all plastic production like injection molding, bottle blowing, film blowing, pipe extrusion, sheet extrusion, etc.

For further details, please contact us at:

Email: [email protected]

WA/Phone: +86-151 3312 6998

QR Code: WA & Wechat