Introduction

In the ever-evolving plastics industry, precision and efficiency are paramount. Gravimetric dosing systems have become essential in the production of high-quality plastic products, including garbage bags. These advanced systems ensure precise measurement and blending of raw materials, leading to consistent product quality, reduced waste, and optimized production costs. This article explores the role of gravimetric dosing systems in garbage bag manufacturing, highlighting their benefits and applications.

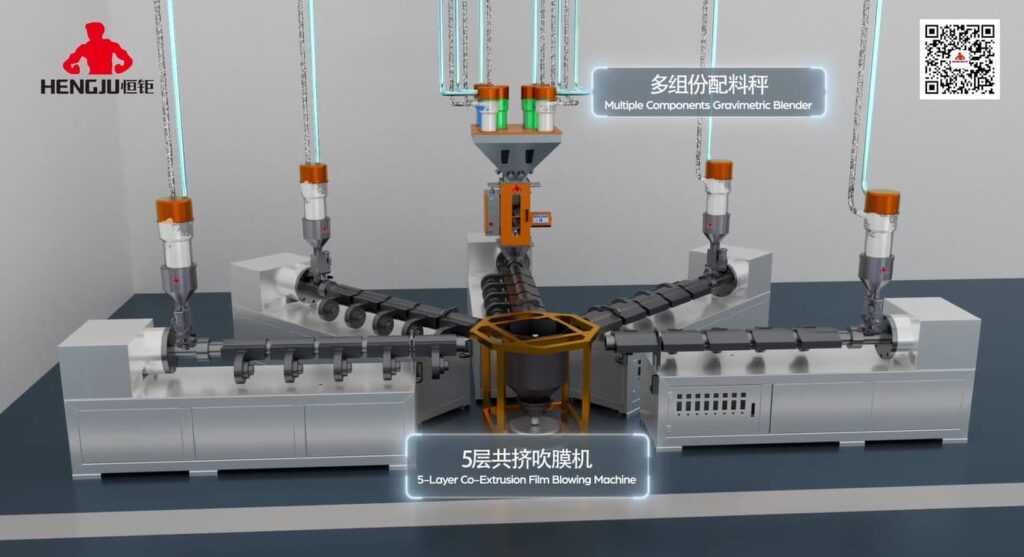

What is a Gravimetric Dosing System?

A gravimetric dosing system is an automated device used to measure and blend various raw materials by weight before they are processed in the production line. Unlike volumetric systems, which measure materials based on volume, gravimetric systems provide higher accuracy and consistency by measuring the actual weight of each component. This precision is crucial for maintaining the desired material properties and product quality.

Benefits of Gravimetric Dosing Systems in Garbage Bag Production

- Enhanced Accuracy and Consistency

- Gravimetric dosing systems ensure that each batch of material is measured with high precision. This accuracy is critical in maintaining the consistency of garbage bag thickness, strength, and other key properties.

- Reduced Material Waste

- By accurately dosing the required amounts of raw materials, gravimetric systems minimize waste. This not only reduces material costs but also contributes to more sustainable production practices.

- Improved Product Quality

- Consistent dosing leads to uniform product quality. For garbage bags, this means fewer defects such as weak spots or inconsistent thickness, which can lead to product failure during use.

- Cost Efficiency

- Accurate dosing reduces the likelihood of overuse of expensive additives and ensures optimal use of all materials. This cost efficiency can be significant in large-scale garbage bag production.

- Flexibility and Scalability

- Gravimetric dosing systems are highly flexible, allowing manufacturers to easily adjust formulations for different types of garbage bags, whether for household, industrial, or commercial use. They are also scalable, making them suitable for small operations as well as large production facilities.

Application in Garbage Bag Production

1. Material Blending

Garbage bags are typically made from a blend of polyethylene (PE) resins, often combined with recycled materials and additives to enhance properties such as strength, flexibility, and color. Gravimetric dosing systems accurately measure and mix these components, ensuring the final blend meets the required specifications.

2. Color and Additive Control

Gravimetric systems are essential in controlling the precise amount of colorants and additives. This is particularly important for producing colored or scented garbage bags, where uniform distribution of additives is necessary for consistent appearance and performance.

3. Process Optimization

Integrating gravimetric dosing systems into the production line allows for real-time monitoring and adjustments. This optimization ensures that any deviations in material flow or weight are quickly corrected, maintaining continuous production efficiency and reducing downtime.

Conclusion

The integration of gravimetric dosing systems in garbage bag production represents a significant advancement in the plastics industry. These systems provide unparalleled accuracy, consistency, and efficiency, leading to high-quality products and cost-effective manufacturing processes. As the demand for durable and reliable garbage bags continues to grow, the role of gravimetric dosing systems will become increasingly important in meeting these industry standards.

By embracing this technology, manufacturers can ensure that their products meet the highest quality standards while also achieving operational excellence and sustainability goals.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico