In the realm of plastic molding manufacturing, the right auxiliary equipment can make a world of difference. Among all, the Gravimetric Blender stands out as a crucial tool for ensuring precision, efficiency, and sustainability.

Plastic Molding Manufacturing and Auxiliary Equipment

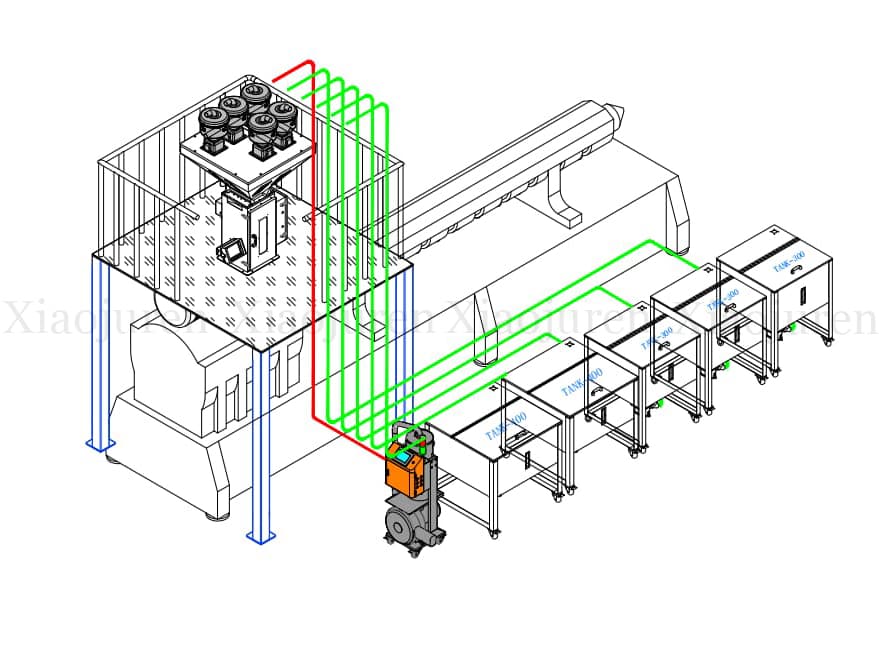

Plastic molding manufacturing involves the transformation of plastic resins into a wide array of products. The process relies heavily on a suite of auxiliary equipment designed to streamline operations and increase productivity.

Gravimetric Blender: A Key Auxiliary Equipment

The Gravimetric Blender, a vital piece of auxiliary equipment, is making a significant impact in this industry. Its capacity to accurately control material quantities ensures a consistent blend, which is crucial for the molding process.

The Value of Precision and Efficiency

With a Gravimetric Blender in their arsenal, plastic molding manufacturers can handle high volumes of materials without sacrificing quality. The device’s adjustable dosing range ensures optimal material usage, reducing waste and boosting overall efficiency.

Safety and Sustainability Considerations

Beyond performance benefits, the Gravimetric Blender also stands tall in terms of safety and sustainability. Its built-in safety features protect operators, while its energy-efficient design contributes to the industry’s push towards greener practices.

Looking Towards the Future

As the demands of the plastic molding manufacturing industry evolve, the role of the Gravimetric Blender is set to expand. Its blend of precision, efficiency, and sustainability positions it as a key player in the future of plastic auxiliary equipment.

The Gravimetric Blender is revolutionizing plastic molding manufacturing. Its integration into the suite of plastic auxiliary equipment is not only enhancing current processes but also paving the way for future advancements. The device’s ability to deliver on precision, efficiency, safety, and sustainability makes it an invaluable tool in this industry.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico