Gravimetric feeders are essential auxiliary machines in the plastics industry, known for their precision in measuring and dispensing materials based on weight. These machines ensure accurate and consistent output, which is crucial for maintaining high-quality production standards. In this article, we’ll explore the various applications of gravimetric feeders within the plastics industry and how they enhance different types of plastic manufacturing processes.

Applications in the Plastics Industry

Gravimetric feeders are widely used in several key areas of the plastics industry, including injection molding, extrusion, blow molding, and compounding. Each application benefits from the precision and efficiency provided by these feeders.

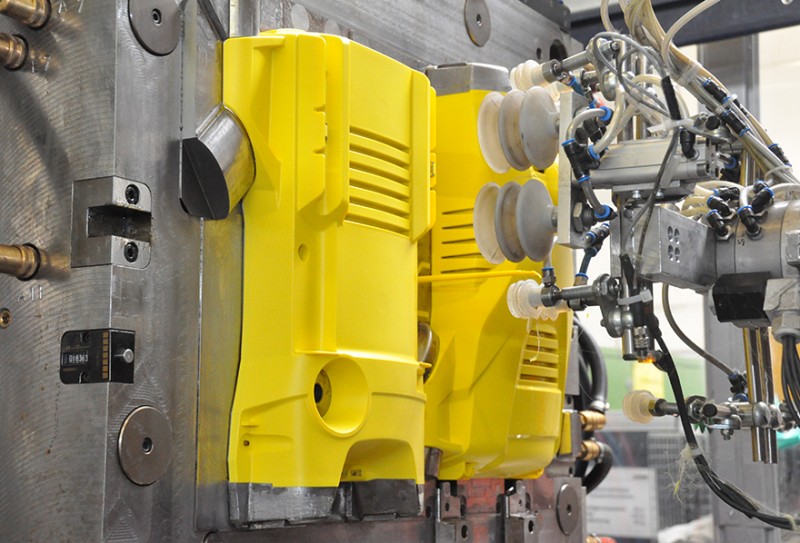

1.Injection Molding FactoriesGravimetric feeders are vital in injection molding factories, where they ensure that plastic resins, colorants, and additives are accurately measured and mixed. This precision is essential for producing high-quality plastic parts with consistent properties. Typical products include automotive components, consumer electronics housings, and various consumer goods.

2.Extrusion PlantsIn extrusion processes, gravimetric feeders guarantee the correct mix of materials, resulting in uniform and high-quality products. These products include plastic films, sheets, pipes, and profiles. The consistent output provided by gravimetric feeders is crucial for applications such as packaging films, construction materials, and industrial components.

3.Blow Molding FacilitiesBlow molding facilities use gravimetric feeders to maintain the correct proportions of raw materials when producing hollow plastic products such as bottles, containers, and tanks. Accurate material mixing ensures product integrity and consistency, which is vital for both consumer and industrial applications.

4.Compounding FacilitiesCompounding involves blending base polymers with additives to create specialized plastic compounds tailored to specific applications. Gravimetric feeders ensure the precise addition of additives like stabilizers, flame retardants, and colorants, leading to uniform and high-performance plastic compounds used in various industries, including automotive, electrical, and construction.

Benefits of Using Gravimetric Feeders

The use of gravimetric feeders in the plastics industry offers several significant benefits:

- Enhanced Product QualityBy ensuring precise material measurement and consistent mixing, gravimetric feeders help maintain high product quality. This precision reduces the risk of defects and ensures that the final products meet stringent industry standards.

- Increased EfficiencyGravimetric feeders automate the material dosing process, reducing manual intervention and the potential for human error. This automation leads to increased production efficiency and reduces downtime, ultimately lowering operational costs.

- Material SavingsAccurate material dosing minimizes waste, leading to significant material savings. This efficiency not only reduces costs but also supports sustainability efforts by reducing the consumption of raw materials.

- Process OptimizationGravimetric feeders provide real-time monitoring and control of material flow, allowing for immediate adjustments to the production process. This capability enhances process optimization, leading to improved overall production performance.

Conclusion

Gravimetric feeders are indispensable in the plastics industry, providing the accuracy and consistency required for high-quality production. From injection molding and extrusion to blow molding and compounding, these feeders enhance efficiency and product quality by ensuring precise material dosing. As the demand for high-performance plastic products continues to grow, the role of gravimetric feeders in optimizing manufacturing processes becomes increasingly important.

For more detailed insights into how gravimetric feeders can benefit your specific application within the plastics industry, consult with leading manufacturers and explore the latest technological advancements in this field.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico