Plastic manufacturing is a complex and vital industry that produces a wide range of products essential to our daily lives. One key aspect of this process involves the use of advanced equipment like Gravimetric Blenders. Let’s delve into the intricacies of plastic manufacturing and explore the role of Gravimetric Blenders.

Understanding Plastic Manufacturing

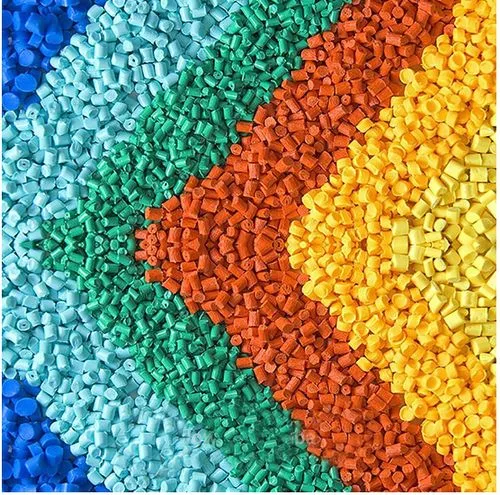

Plastic manufacturing is a methodical process that begins with raw materials such as polymers, additives, and colorants. These materials are carefully selected based on the desired properties of the final plastic product. The manufacturing process involves several stages, including compounding, shaping, and finishing.

Role of Gravimetric Blenders

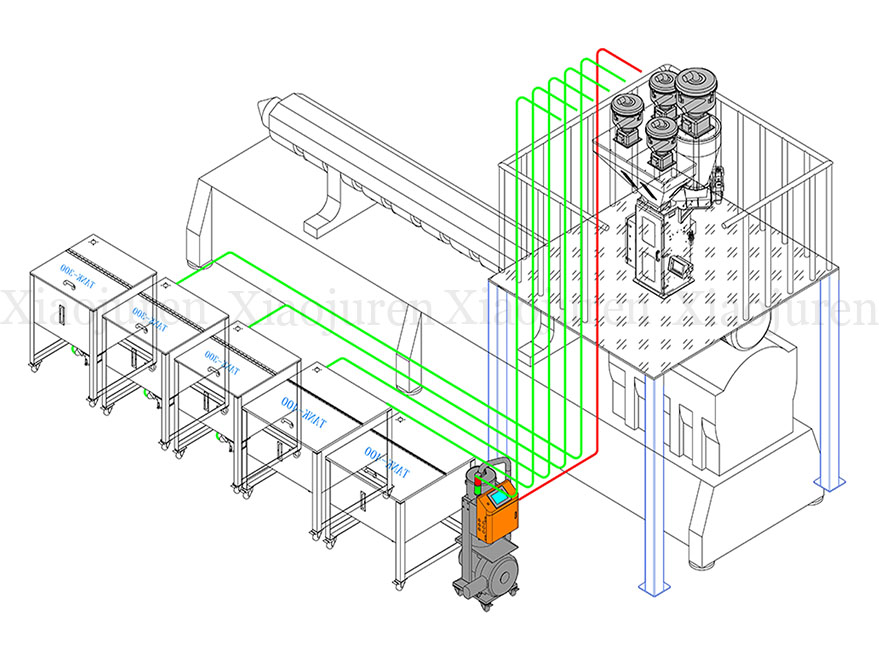

Gravimetric Blenders are sophisticated devices crucial in the compounding phase of plastic manufacturing. These blenders precisely mix and blend raw materials in accurate proportions based on weight measurements. Unlike traditional volumetric blenders, which rely on volume measurements, gravimetric blenders offer superior accuracy and consistency.

How Gravimetric Blenders Work

Gravimetric Blenders utilize load cells to measure the weight of each ingredient as it is added to the blending chamber. This precise measurement ensures that the correct ratio of materials is maintained throughout the compounding process. The blender then homogenously mixes these materials to create a uniform plastic mixture ready for further processing.

Benefits of Gravimetric Blenders

1.Accuracy: Gravimetric Blenders provide unparalleled accuracy in material dispensing, leading to consistent product quality.

2.Efficiency: By automating the blending process, these devices reduce human error and optimize production efficiency.

3.Flexibility: Manufacturers can easily adjust formulations and batch sizes to meet specific requirements.

4.Quality Control:Gravimetric blending enhances quality control by minimizing material wastage and ensuring batch-to-batch consistency.

Plastic manufacturing, with innovations like Gravimetric Blenders, continues to evolve, offering precise control over material blending and enhancing product quality. By understanding the role of such equipment in the manufacturing process, businesses can optimize operations and deliver high-quality plastic products to various industries worldwide.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico