In the realm of plastic sheet extrusion, particularly for PP (Polypropylene), PS (Polystyrene), and PET (Polyethylene Terephthalate), the Gravimetric Blender with Screw Feeder emerges as a revolutionary solution. This specialized blender is designed to accommodate the unique needs of customers who utilize a significant amount of crushed materials, including recycled materials from trim edges and thermo-waste rolls.

Operating Principle

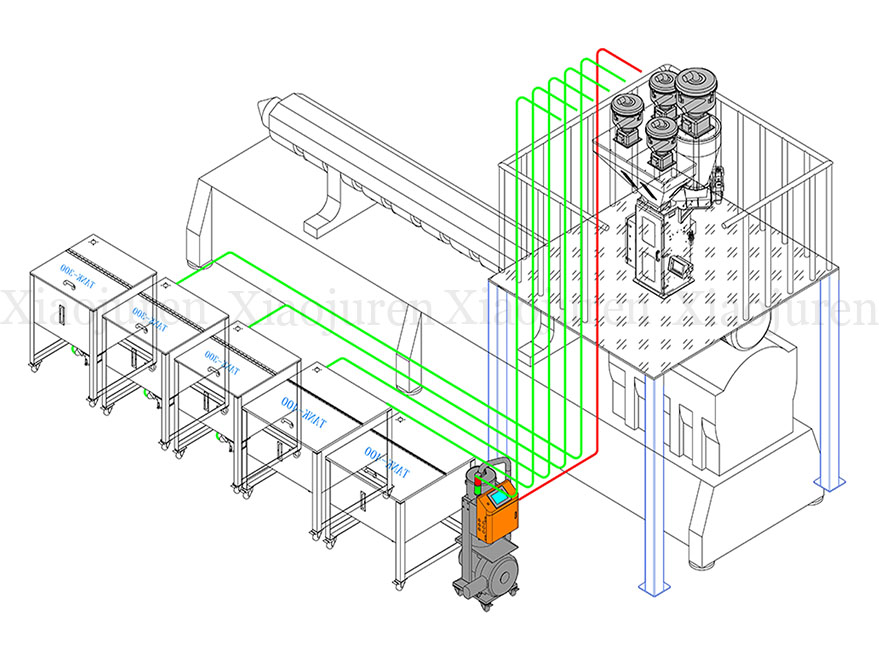

The blender operates on the principle of gravimetric blending, ensuring precise weight-based dosing and blending of materials. It’s capable of dosing 4-8 components, making it adaptable to various blending requirements. The Screw Feeder, an integral part of this system, allows for feeding recycled material with irregular sizes, thus preventing issues such as blockages or bridging that often plague traditional gravimetric batch blenders.

Key Advantages

This specialized blender boasts several superior features. It stores up to 100 recipes for convenient retrieval and utilization, enhancing operational efficiency. The advanced control algorithms incorporated into the device allow for autonomous optimization and automatic calibration, further ensuring high accuracy in material dosing.

The blender stands out with its Etherhet interface. Attached to the controller and working in conjunction with the relevant software, it enables the transmission of material proportion data, such as maximum output, actual output, and dosing accuracy, thereby contributing significantly to quality control.

In addition, the blender is equipped with a sound and flash alarm system, promptly and clearly informing operators of necessary repairs. The design allows for the simultaneous feeding of multiple recycled flakes through the screws, ensuring a fast dosing rate and large dosing capacity, crucial for sheet extrusion processes.

Facilitating Factory Automation

By mechanizing the blending process, this Gravimetric Blender with Screw Feeder promotes factory automation. It reduces manual intervention, thereby boosting productivity and efficiency.

In conclusion, this specialized Gravimetric Blender with Screw Feeder is a game-changer for PP, PS, and PET sheet extrusion. With its precise blending capabilities, versatility, efficiency, and facilitation of factory automation, it stands as an invaluable asset in the plastic auxiliary forming equipment industry. Its specific design to handle crushed materials makes it an indispensable tool, revolutionizing the landscape of the plastic sheet extrusion industry.

If you need a central conveying system, please visit https://centralconveyingsystem.com/

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico