In the ever-evolving plastic molding industry, finding ways to improve efficiency, maintain quality, and reduce waste is always at the forefront. This is where the Gravimetric Blender steps in, serving as a pivotal tool in the operations of a plastic molding company.

Navigating the Plastic Molding Landscape

Plastic molding is a versatile and intricate process that involves shaping plastic using a rigid frame or model. This process is widely adopted due to its ability to produce high-quality and intricate plastic parts. As such, plastic molding companies constantly strive to optimize their processes to achieve greater efficiency and precision.

The Role of the Gravimetric Blender

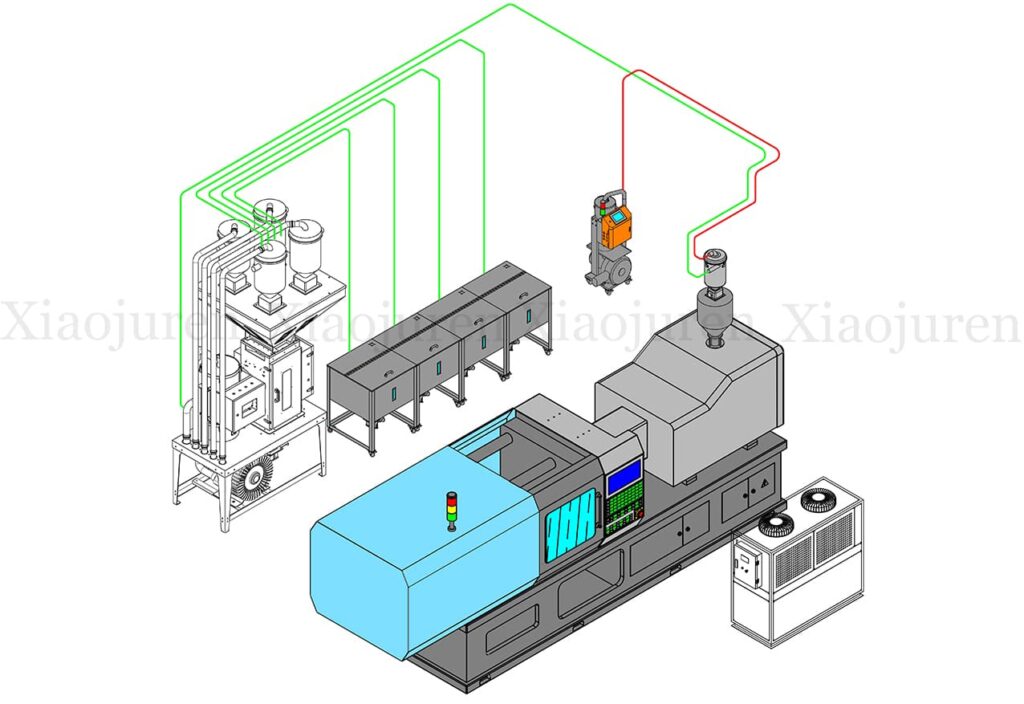

In an industry that demands accuracy and efficiency, the Gravimetric Blender has come to the fore as a game-changer. This device ensures precise weight-based control and mixing of materials, making it an indispensable tool in a plastic molding company.

Boosting Efficiency and Precision

The Gravimetric Blender’s strength lies in its ability to mix large quantities of material with an adaptable dosing range, greatly improving operational efficiency in a plastic molding company. It simplifies operations by reducing the need for constant loading, ensuring optimal use of materials. Its accurate measurements and consistent blending also contribute to the quality of the final product, making it an invaluable asset in the plastic molding process.

Emphasizing Safety and Sustainability

Along with efficiency and precision, the Gravimetric Blender also prioritizes safety and sustainability. It includes safety features that protect both the operators and the environment. Furthermore, its energy-efficient operation aligns with the increasing emphasis on sustainable practices in the plastic molding industry.

Looking Toward the Future

With technological advancements paving the way for innovative solutions, the Gravimetric Blender’s potential in plastic molding is immense. As the industry continues to evolve towards greater efficiency and sustainability, this dynamic device is set to play a significant role in shaping the future of plastic molding.

The Gravimetric Blender has become a cornerstone in a plastic molding company’s operations. It symbolizes how innovative solutions can enhance efficiency, accuracy, safety, and sustainability within the industry. Looking ahead, the Gravimetric Blender’s role is set to become even more vital, ushering in a new era of plastic molding that aligns with the principles of efficiency, safety, and sustainability.

For more plastic auxiliary equipment, please click >>>>

Recommended related articles

- Dosagem de Materiais para Embalagens Alimentícias: Precisão e Eficiência na Produção

- Como o Dosador Gravimétrico Melhora a Produção de PET Sheet e Pré-formas

- How Gravimetric Blenders Improve Energy Efficiency and Sustainability

- Como o Dosador Gravimétrico Melhora a Qualidade do Produto Final

- Como Melhorar a Eficiência na Produção com o Dosador Gravimétrico